Click on the arrows below for information about periodic requirements that should be completed to operate your tank system in compliance.

Release Detection

Monthly release detection is required for all regulated tanks. Common methods include interstitial monitoring, ATG (automatic tank gauge) testing and SIR (statistical inventory reconciliation). Tank owners/operators must obtain at least one passing test result for each tank every month.

The following requirements apply for each of the common release detection methods.

Interstitial monitoring

- Need a documented "normal" sensor status report for each tank every month or a written log of monthly observations of the interstice

- Monthly interstitial monitoring may be used in place of annual line testing (if product piping is double-walled)

All UST systems installed during and after 2008 must use interstitial monitoring as the primary release detection method

- ATG

- Need a documented passing tank test for each tank every month

- For tanks with low fuel levels: obtain monthly passing tests by maintaining adequate fuel volume or by upgrading to continuous statistical leak detection

- For ATG systems that are capable of conducting monthly product line tests at a leak rate of 0.2 gph (gallons per hour): you may use these tests in place of annual line testing at 0.1 gph as long as the results clearly indicate "line test‚" versus "tank test."

- SIR

- Data must be submitted to a certified SIR vendor as soon as possible after the end of each month to ensure you will receive your SIR report no later than 20 days after the end of the month

- Inconclusive or failed SIR results that are not overturned by the third-party SIR vendor within 24 hours of receiving the report from the vendor must be reported to OPS as a suspected release

- A tank owner may choose to avoid SIR due to delayed release discovery and the ongoing expense associated with a SIR vendor

USTs for Emergency Generators

Owners of existing USTs used solely for emergency generators must begin performing release detection on the tank(s) and piping by January 1, 2020. Owners of USTs installed after January 1, 2017, used solely for emergency generators must perform release detection as soon as they are put into use.

Monthly Inspections

The UST Monthly Compliance Inspection Checklist should be completed each month. Maintain these records for a minimum of 12 months and make them available for OPS review. The Class A or Class B Operator should conduct these inspections but can delegate this duty to a person familiar with the fueling system if necessary.

Tips for Monthly Inspections

- Print or log your monthly release detection results or send inventory results to the SIR vendor. Include lines unless you perform annual line testing at 0.1 gph.

- The Monthly Compliance Inspection is divided into five main parts, for which OPS has produced helpful videos to walk you through the requirements.

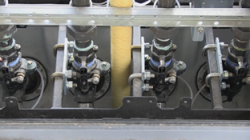

OPS recommends opening dispenser cabinets during Monthly Compliance Inspections. |

- Any product leakage or seeping connections should be addressed immediately. If product has come in contact with soil or groundwater, the tank owner/operator is required to report a suspected release to the OPS Technical Assistance Line at (303) 318-8547.

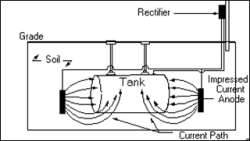

- If your UST system has impressed current cathodic protection, the system must be operated and maintained to continuously provide corrosion protection to the metallic components. The impressed current cathodic protection system must be inspected every 60 days to ensure that it is operating correctly; however, OPS recommends that this inspection be completed every 30 days. Rectifier readings will be required for the period specified in the Annual Compliance Package.

Release Detection

Annual line tightness testing is required for pressurized product piping that is not monitored monthly.

- Utilize your automatic tank gauge system for piping release detection. Ensure your ATG is programmed to test both the piping and the tanks.

- You must produce an annual passing 0.1 gph line test or have a tank system subcontractor perform a 0.1 gph line pressure test.

Annual leak detector testing is required for all pressurized product piping.

- Utilize your ATG system for leak detector testing.

- You must produce an annual passing 3.0 gph leak detector functionality test or have a tank system subcontractor perform a 3.0 gph leak detector functionality test.

It is important to contact OPS immediately after failed or inconclusive tank system tests, and to work with your contractor to identify, repair, and retest. Don't forget to submit the passing results to OPS as part of your records request.

USTs for Emergency Generators

Owners of existing USTs used solely for emergency generators must begin performing release detection on the tank(s) and piping by January 1, 2020. Owners of USTs installed after January 1, 2017, used solely for emergency generators must perform release detection as soon as they are put into use.

Release Detection Equipment Inspections

Tank systems rely on a variety of equipment to detect releases. From something as simple as a tank gauge stick to something as complicated as a positive shutdown containment sump sensor, it is critical that this equipment function properly.

Release detection equipment including automatic tank gauge (ATG) probes/floats, sump sensors, associated electronic control equipment and tank gauging devices must be inspected by January 1, 2020, and every year thereafter. The inspection must be performed in accordance with manufacturer's recommendations, a standard code of practice or another OPS-approved method. A common way to ensure your inspection is valid is to use the industry's primary code of practice - Petroleum Equipment Institute's RP1200.

For example, an inspection for a tank system that relies on an ATG for release detection should include the following steps, at a minimum:

1. ATG and other controllers

a. Test alarm

b. Verify system configuration

c. Test battery backup

2. Probes and sensors

a. Remove and inspect for residual buildup

b. Ensure floats move freely

c. Ensure shaft is not damaged

d. Ensure cables are free of kinks and breaks

e. Test alarm operability and communication with controller

This inspection will help ensure your release detection is being conducted properly and will help you discover a release quickly should one occur.

The record of this inspection must be kept for at least one year.

Annual Inspections

Annual testing and inspections should be conducted within 12 months of the previous test or inspection, regardless of when OPS requests these records.

An Annual Compliance Inspection is required for all UST systems. It is intended to help identify leaks and to monitor the condition of tanks, piping, secondary containment and equipment. This inspection is more thorough than, and is to be conducted in addition to, the monthly compliance inspections.

Tips for Annual Inspections

- A certified Class A or Class B Operator must conduct these inspections, provide the owner/operator with a copy and alert the owner/operator of any condition discovered during the inspection that may require follow-up actions. The inspection that an OPS inspector conducts at your facility is not a substitute for your annual inspection.

- A UST annual compliance inspection should be performed within 12 months of the previous one and will be required to be submitted to OPS for the period specified in the Annual Compliance Package.

- The annual compliance inspection is divided into 10 main parts, for which OPS has produced helpful videos to walk you through the inspection.

- If your leak detector fails, it must be replaced or repaired and a passing 3.0 gph functionality test must be documented. Submit the passing results to OPS as part of the annual records request.

Spill Bucket Testing

The purpose of spill bucket testing is to ensure the spill bucket will hold small spills when the delivery hose is disconnected from the fill pipe. All single-walled buckets, containers and basins used for spill protection on a UST must be tested by January 1, 2020, and every three years thereafter. OPS provides a Secondary Containment Testing form that you can use to document the testing. OPS strongly recommends hiring a tank system subcontractor to perform your spill bucket testing.

Spill bucket testing must be performed in accordance with manufacturer’s recommendations, a standard code of practice or another OPS-approved method. The most common methods for testing include hydrostatic (water level) testing and vacuum testing. A good way to ensure your test is valid is to use the industry’s primary code of practice - Petroleum Equipment Institute’s RP1200.

Hydrotesting is relatively easy to perform, but management of the water following the test can be challenging. The test water can be reused for similar testing at other sites. However, once the test water is no longer useful, it must be collected and disposed of at a permitted treatment facility or discharged under a permit from the Colorado Department of Public Health and Environment. It is illegal to dispose of test water to the ground surface, into storm drains or into the sanitary sewer system without proper permitting.

Drain valves found at the bottom of spill buckets are common sources of failure. It is important to ensure the drain valve is properly closed and seated prior to performing the test and during operation of the tank system.

Instead of performing the three-year hydrostatic or vacuum tests described above, owners of double-walled spill buckets can choose to check and document the interstitial gauge on a monthly basis, as follows:

- For double-walled equipment installed before January 1, 2017, a tightness test of the interstitial space must be conducted per manufacturer's instructions (most likely vacuum testing) by January 1, 2020. After this initial test, monthly interstitial observations will be accepted as an alternative to testing every three years.

- For double-walled equipment installed after January 1, 2017, a tightness test of the interstitial space must be conducted at installation per manufacturer's instructions (most likely vacuum testing performed before the equipment is buried and then again after concrete has been poured). After these initial installation tests, monthly interstitial observations will be accepted as an alternative to testing every three years. As a reminder, tightness testing must be performed again within 30 calendar days of one year thereafter, as has been required by regulation since August 1, 2008.

Additionally, the primary (or inner) bucket of double-walled spill buckets can be repaired or replaced without breaking concrete, making this a cost-effective option if replacement of your existing buckets is necessary. These types of spill buckets are a bit more expensive to install, but they can reduce testing and repair costs in the future.

Records of spill bucket testing need to be kept for three years.

Please use the UST Minor Equipment Repair/Replacement Notification form to notify OPS of spill bucket replacements.

Secondary Containment Testing

USTs and piping installed after August 1, 2008, are required to have secondary containment and use interstitial monitoring as the tank and piping release detection method. Secondary containment is meant to help prevent fuel releases from impacting the environment, so it is important to ensure the containment devices are liquid-tight.

OPS has required secondary containment testing at the time of installation and approximately one year thereafter since 2008. Containment sumps used for piping interstitial monitoring must be tested by January 1, 2020, and every three years thereafter. If you use interstitial monitoring for your piping release detection (which includes all piping installed after August 1, 2008), you need to have the containment sumps (under dispenser containment, submersible turbine pump containment and any piping transition sumps) tested. This requirement also applies to underground piping systems connected to aboveground storage tanks if interstitial monitoring is used for piping release detection.

Secondary containment must be performed in accordance with manufacturer’s recommendations, a standard code of practice or another OPS-approved method. The most common method for testing is hydrostatic (water level) testing. A good way to ensure your test is valid is to use the industry’s primary code of practice - Petroleum Equipment Institute’s RP1200. The hydro test procedure in RP1200 requires filling containment sumps to a level above all piping and conduit penetrations. However, if the containment sump is equipped with a liquid level sensor (mounted below the penetration points) that automatically activates a shutdown of the UST system, OPS will allow the sump to be filled up to the level of the sump sensor during the three-year test.

Hydrotesting is relatively easy to perform, but management of the water following the test can be challenging. The test water can be reused for similar testing at other sites; however, once the test water is no longer useful, it must be collected and disposed of at a permitted treatment facility or discharged under a permit from the Colorado Department of Public Health and Environment. It is illegal to dispose of test water to the ground surface, into storm drains or into the sanitary sewer system without proper permitting.

Double-walled containment sumps with interstitial monitoring between the walls can be checked monthly via their interstitial gauges and are not required to meet the three-year testing requirement. These types of containment sumps are more expensive to install, but they can reduce testing and repair costs in the future.

Please use the Secondary Containment Testing Form to document the test.

Records of secondary containment testing need to be kept for three years.

Additionally, though not a requirement, OPS strongly recommends testing the secondary piping while you’re performing this containment sump testing. Given that the containment sumps need to be hydraulically isolated from the secondary piping for testing, it is relatively easy to also test the secondary piping at that time.

Double-walled containment sumps with interstitial monitoring between the walls can be checked monthly via their interstitial gauges and are not required to meet the three-year testing requirement. These types of containment sumps are more expensive to install but can reduce testing and repair costs in the future.

Fuel within the secondary containment device is not considered a suspected release unless the liquid level is at or above containment wall penetrations. The bottom seal of a submersible turbine pump containment is considered a penetration, so fuel above that seal would be a suspected release. Tank owners/operators must report suspected releases to OPS at 303-318-8547 within 24 hours of discovery.

Please use the Secondary Containment Testing Form to document the test. As with other three-year requirements, records of secondary containment testing need to be kept for three years.

Overfill Prevention Equipment Inspections

All underground storage tanks (USTs) that receive deliveries that are in excess of 25 gallons must have an overfill prevention device. These devices commonly include drop tube valves, vent line restrictors (ball floats) and overfill alarms. The purpose of these devices is to shut off or slow the delivery of product into the UST to avoid overfilling.

Devices used for overfill prevention on a UST must be inspected by January 1, 2020, and every three years thereafter. The inspection must be performed in accordance with manufacturer’s recommendations, a standard code of practice or another OPS-approved method. A common way to ensure your inspection is valid is to use the industry’s primary code of practice - Petroleum Equipment Institute’s RP1200.

Overfill prevention devices must typically be removed to perform this inspection. The inspection should verify the levels, orientation, condition and proper operation of the device. During reinstallation, drop tube valves must be oriented properly so the float doesn’t contact tank walls.

Problems with overfill prevention devices can occur due to corrosion, float or valve damage or improper installation. Removing the devices for inspection can be quite challenging due to corrosion or access issues. OPS strongly recommends hiring a tank system subcontractor to perform these inspections.

As with other three-year requirements, records of this inspection need to be kept for three years.

Cathodic Protection Testing

Two methods of corrosion protection - galvanic and impressed current - must be tested by a qualified cathodic protection tester, at least every three years, to ensure adequate protection of all metallic tank system components in contact with soil or water. Test reports of passing or failing results for the period specified are required. These test reports shall include the name of the facility, OPS Facility ID, and the facility's physical address. The test reports shall also include a concise narrative explaining the testing process used, the test results, and must also include a listing of the tanks system components being protected. A site aerial map with a north arrow, map scale, and a map key must also be included.

Suction Piping Testing

Conduct a line tightness test on UST systems with underground suction piping at least once every three years. Safe or European suction piping does not require tightness testing if it meets all of the following criteria:

- Operates at less than atmospheric pressure

- Sloped so that product drains back into the storage tank

- Includes only one check valve in each suction line that is located directly below and as close as practical to the suction pump