Tank Closure

There are a number of reasons why owners/operators may need to stop using their tanks, either temporarily or permanently. OPS allows three types of closure: seasonal, temporary and permanent.

Closure of a tank system can be a complicated and dangerous task for an owner/operator. OPS highly advises the use of qualified tank removal contractors and environmental consultants.

It is important for the owner/operator and the consultant to have a plan in place prior to beginning closure activities. The economic issues, disposal facilities, additional equipment needed and feasibility of emergency response must be considered prior to starting closure activities to effectively abate contamination to reduce risk of exposure.

OPS considers tanks to be currently in use unless seasonal, temporary or permanent closure requirements have been completed.

| Tank Status | Description |

|---|---|

| Currently in use | More than one inch of product in tank. |

| Seasonal closure | Less than one inch of product in tank and unused for up to six consecutive months each year. |

| Temporary closure | Less than one inch of product in tank. |

| Permanent closure | All liquids and sludges are removed from tank system, and it is never used again to store regulated substances. |

More information about the requirements for each closure type are described below.

Seasonal Closure

Owners/operators who operate a seasonal business are required to notify OPS prior to the start of the first seasonal operation. The notice of seasonal operation can be emailed to us at cdle_oil_inspection@state.co.us.

- Seasonal Closure Criteria

Facilities may not be placed in seasonal closure for longer than six months at a time. The owner/operator must provide documentation related to tank pump-down at the end of the season.

- The tank must be emptied and additional release detection is not required as long as the tank system is empty, which occurs when all materials have been removed using commonly-employed practices such that no more than one inch of residue, or 0.3% by weight of the total capacity of the tank system, remains in the system.

- The owner/operator must maintain certified Class A, B and C Operators for USTs.

- When a tank system is closed for the season, the owner/operator must continue operation and maintenance of corrosion protection. This includes three-year corrosion protection system testing and recording 60-day rectifier readings, if applicable.

- The annual registration fee ($35 per tank) still applies.

At the end of the seasonal period, the owner/operator must put the tank system back into service, place it into proper temporary closure or permanently close it.

Temporary Closure

If the tank system is not going to be operated and the owner isn't sure when operations will begin, or if the tank system does not contain enough fuel to perform release detection, the owner may put the tank system into Temporary Closure. OPS may allow a temporary closure of tank systems for a period of up to 12 months. After the 12-month temporary closure period has elapsed, the owner/operator must put the tank system back into service, permanently close it or request an extension.

For a tank to be properly placed into temporary closure the following criteria must be met:

- UST

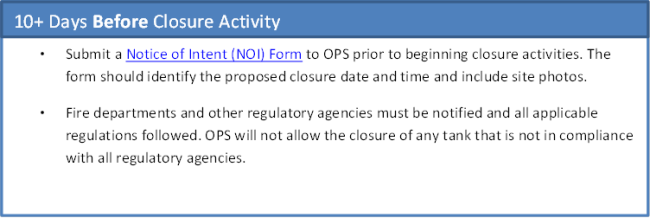

- Notify OPS in writing at least 10 calendar days prior to placing a tank system into temporary closure.

- Submit 12 months of release detection and corrosion protection records for lines and tanks or a precision tightness test on tanks and a limited site assessment.

- Remove the regulated substance from the tank such that no more than one inch remains and provide documentation to OPS.

- Vent lines must be left open and functioning.

- If the temporary closure period is three months or more, all pumps, manways, ancillary equipment and lines (other than vent lines) must be capped and secured, unless an alternate schedule is approved.

- Because the tanks must be emptied, release detection is not required.

- The owner/operator must maintain certified Class A, B and C Operators.

- The owner/operator must continue operation and maintenance of corrosion protection.

- This includes three-year corrosion protection system testing and recording 60-day rectifier readings, if applicable.

- The owner/operator must complete and submit an Annual Compliance Inspection.

- The annual registration fee ($35 per tank) still applies.

- AST

- Notify OPS in writing at least 10 calendar days prior to placing a tank system into temporary closure.

- Submit 12 months of monthly visual inspections, inventory control, ullage records, piping release detection records and corrosion protection testing (if applicable) for tanks and piping or conduct a tightness test of the tanks and underground piping and complete a limited site assessment.

- Remove the regulated substance from the tank such that no more than one inch remains and provide documentation to OPS.

- The AST must be safeguarded against trespassing by means of locked gates, fences, etc.

- Vent lines must be left open and functioning.

- If the temporary closure period is three months or more, all pumps, manways, ancillary equipment and lines (other than vent lines) must be capped and secured, unless an alternate schedule is approved.

- Because the tanks must be emptied, release detection is not required.

- The owner/operator must continue operation and maintenance of corrosion protection.

- This includes three-year corrosion protection system testing and recording 60-day rectifier readings, if applicable.

- The owner/operator must complete an Annual Visual Inspection. The $35 per tank annual registration fee still applies.

Temporary Closure Extension

After 12 months of temporary closure, the owner/operator must put the tank system back into service, permanently close it or request an extension to the temporary closure period. If an extension is desired, the owner/operator must submit an extension request and site assessment results in writing. OPS will determine and communicate the new temporary closure end date based upon equipment risk, operational compliance and environmental impacts.

OPS requires owners to permanently close their tanks or put them back into service once they've reached the end of their temporary closure extensions.

- Conducting a Site Assessment for UST Temporary Closure

These site assessment requirements must be followed if you don't have release detection records for temporary closure or if you are extending temporary closure.

Soil Sampling to Meet the Site Assessment Requirement

- The excavation or soil boring must be located no further than five feet from the edge of the tank and must be advanced to a depth of two times the projected vertical distance from the ground surface to the bottom of the tank basin. For example, if the native soil below a tank is estimated to be 12 feet below the ground surface and the sampling surface location is five feet from the end of the tank, the minimum depth of the investigation must be 24 feet.

- If a site assessment is being conducted for one UST, two sampling locations are required - one at each end of the tank or one on each side of the tank.

- If a site assessment is being conducted for multiple tanks, a minimum of four boring locations is required: one location at each corner of the tank basin or one location near the middle of each side of the tank basin.

- A sample must be collected when groundwater is encountered during any site assessment.

Groundwater Sampling to Meet the Site Assessment Requirement

- When shallow groundwater is present and any portion of the tank system is submerged, groundwater sampling is required. Groundwater samples collected from tank basin monitoring points are acceptable.

- One strategically placed groundwater sample collected from an area immediately downgradient of the tank area will meet the site assessment requirement. The inferred groundwater flow direction must be verified by local groundwater flow information or projected using fundamental hydrodynamic principles.

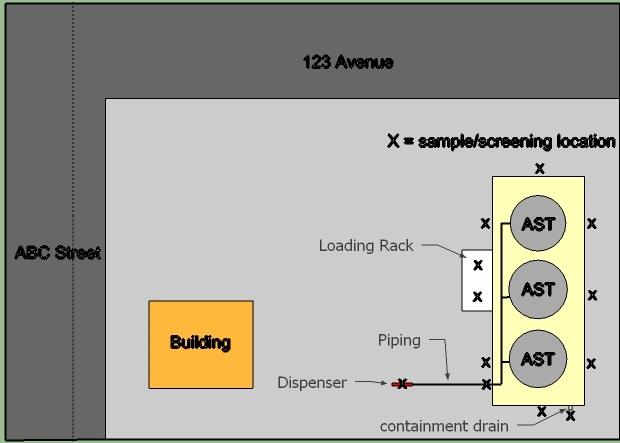

- Conducting A Site Assessment for AST Temporary Closure

These site assessment requirements must be followed if you don't have release detection records for temporary closure or if you are extending temporary closure.

Each AST installation is different and will require that the owner/operator submit pictures of the tank and surrounding area with the request to apply for temporary closure or extend temporary closure when release detection records are not available.

The pictures, which will allow OPS and the owner/operator to develop a site assessment plan to meet the temporary closure requirement, must include the following, at a minimum:

- A panoramic view of the tanks and surrounding area

- The inside of the containment structure and containment drain outfall areas (if present)

- The fuel loading and dispensing areas

If further site assessment is required, owners/operators should utilize the AST closure requirements below to develop the temporary closure site assessment.

Sampling to Meet the Site Assessment Requirement

- Soil sampling will depend on the type of tank system.

- Groundwater sampling is an accepted procedure to meet the site assessment requirement.

- One strategically-placed groundwater sample collected from an area immediately downgradient of the tank area will fulfill the site assessment requirement. The inferred groundwater flow direction must be verified by local groundwater flow information or projected using fundamental hydrodynamic principles.

Back In Service

- UST

Owners/operators should submit a completed Notice of Intent to Place Underground Storage Tanks Back into Service form no more than 30 calendar days prior to placing a UST back in service, and at that time they should also submit corrosion protection records (if applicable) for the period of temporary closure and documentation of passing tightness tests (including ullage) for the tanks conducted within the past 30 calendar days. Owners/operators should obtain passing line and leak detector tests immediately following the introduction of fuel into the lines and submit documentation of testing to OPS within 10 calendar days.

- AST

Owners/operators should submit a completed Notice of Intent to Place Aboveground Storage Tanks Back into Service form no more than 30 calendar days prior to placing an AST back in service, and at that time they should also submit corrosion protection records (if applicable) for the period of temporary closure and documentation of passing tightness tests for the AST that were conducted within the past 30 calendar days. Owners/operators should obtain passing tightness tests for underground lines immediately upon the introduction of fuel into the lines and submit documentation of testing to OPS within 10 calendar days.

Permanent Closure

Once owners/operators are ready to permanently close their tank systems, all liquids and sludges must be removed and the following process must be followed.

The completed report should then be sent via email to cdle_oil_inspection@state.co.us or mailed to the address listed on the form.

- UST Closure Sampling Requirements

Owners/operators can choose one of three ways to permanently close their tanks: closure by removal, closure in place or change in service.

Closure by Removal Closure in Place Change in Service to an Unregulated Substance - Contact the local fire department.

- Ensure site security during closure activities.

- Empty and clean the tanks.

- Secure all tank openings, except one vent line, at a minimum of eight feet above the top of the tank.

- Confirm the tank internal atmosphere is vapor-free prior to moving.

- Secure the tanks on a transport device and replace the vent with one ¼-inch vent opening. All applicable transportation laws and regulations must be followed, including those of the US Department of Transportation.

- All product piping must be emptied, cleaned and capped or removed. OPS prefers that product piping be removed at the time of closure.

- Dispose of the tanks properly.

- Perform an environmental site assessment.

- Contact the local fire department to determine whether closure in place is permissible.

- Empty and clean the tanks.

- All product piping must be emptied, cleaned and capped or removed. Piping must be disconnected from the tanks. OPS prefers that product piping be removed at the time of closure.

- Confirm that the tank internal atmosphere is vapor-free.

- Tanks must be filled with an inert solid material, such as sand or flow fill.

- Secure all tank openings.

- Perform environmental site assessment.

- Empty and clean the tanks.

- All product piping must be emptied and cleaned or removed. OPS prefers that product piping be removed at time of closure.

- Confirm that the tank internal atmosphere is vapor free.

- Perform an environmental site assessment.

Site Assessment Requirements

Integral parts of a closure site assessment include:

- A visual site inspection to identify the presence of petroleum staining

- Soil screening with an organic vapor analysis instrument

- Soil sample collection to define the extent of the impacts in a vertical and horizontal direction

- Laboratory analysis

Tank Samples

For tanks that are removed, native soil samples are required to be taken from beneath each end of the tank, and for tanks greater than 1,000 gallons, samples are also required from below the center of the tank.

If shallow groundwater is encountered during removal, a sample must be collected and analyzed in a laboratory. Native soil samples should then be collected directly above the water table from native soil on each sidewall of the excavation.

For tanks that are left in place (closed in place or change in service), soil samples must be collected from locations and depths most likely to identify contamination (e.g., if the native soil below a tank is estimated to be 12 feet below the ground surface and the sampling surface location is five feet from the end of the tank, the minimum depth of the investigation must be 24 feet). At a minimum, samples must be collected from each end of the tank and from each side. If groundwater is encountered, it must be sampled, and soil samples must be collected from above the groundwater table.

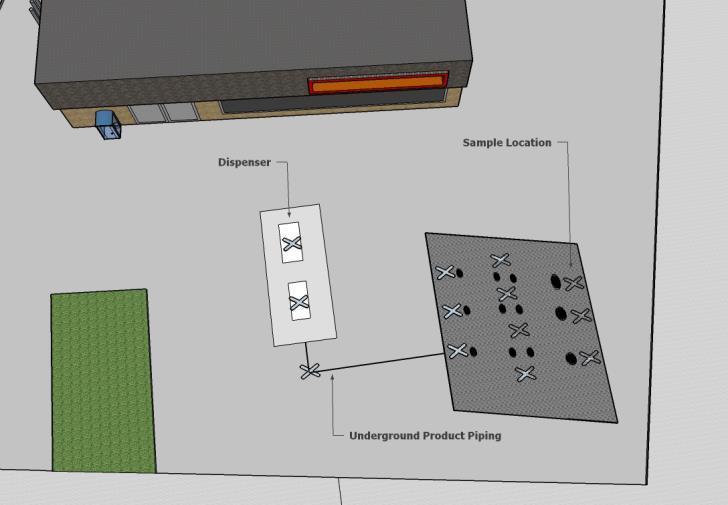

Piping Samples

Underground piping must be sampled at all points where a change in product flow direction occurs within the piping (turns).

If piping is removed, samples must be obtained from native soil directly below the piping.

If piping is left in place, a soil sample boring must be advanced within three feet of the piping and screened for the presence of a release to a minimum of 10 feet below ground surface.

Dispenser Samples

One sample is required directly beneath each dispenser from native soil.

Assessment Results

If the assessment shows that contaminant concentrations are below the current State standards, the owner/operator can request that a No Further Action (NFA) status be given to the permanently closed UST in the closure report. If the assessment shows that contaminant concentrations are above the current State standards, the release must be assessed.

- AST Closure Sampling Requirements

Owners/operators can choose one of three ways to permanently close their tanks: closure by removal, closure in place or change in service.

Closure by Removal Closure in Place Change in Service to an Unregulated Substance - Ensure site security during closure activities.

- Empty and clean the tank.

- All product piping must be emptied, cleaned and capped or removed. It is highly recommended that product piping is removed at the time of closure.

- Secure all tank openings except one vent line.

- Confirm that the internal tank atmosphere is vapor-free prior to moving.

- Secure the tank on a transport device and replace the vent with one ¼-inch vent opening. All applicable transportation laws and regulations must be followed, including those of the US Department of Transportation.

- Dispose of the tank properly.

- Perform an environmental site assessment.

- Contact the local fire department to determine whether closure in place is permissible.

- Empty and clean the tank.

- All product piping must be emptied, cleaned and capped or removed. Piping must be disconnected from the tank. It is highly recommended that product piping is removed at the time of closure.

- Secure all tank openings.

- Keep vents active.

- Confirm tank internal atmosphere is vapor-free.

- To return an AST back to service containing a regulated substance, the tank would have to be inspected and re-certified per the tank manufacturer, and permitted through OPS.

- Perform an environmental site assessment.

- Empty and clean the tank.

- All product piping must be emptied, cleaned and capped or removed. It is highly recommended that product piping is removed at time of closure.

- Confirm that the tank internal atmosphere is vapor-free.

- To return an AST back to service containing a regulated substance, the tank would have to be inspected and re-certified per the tank manufacturer, and permitted through OPS. OPS will not allow a tank that has held an incompatible substance for that tank (e.g., water in a steel tank) to be brought back into service.

- Perform an environmental site assessment.

Site Assessment Requirements

Integral parts of a closure site assessment include:

- A visual site inspection to identify the presence of petroleum staining

- Soil screening with an organic vapor analysis instrument

- Soil sample collection to define the extent of the impacts in a vertical and horizontal direction

- Laboratory analysis.

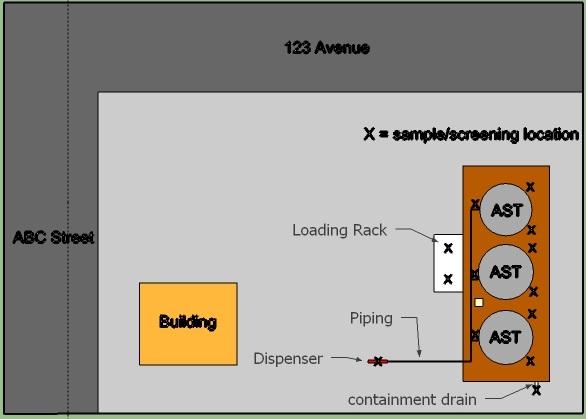

Samples Required for All Sites

Sample Location Required Sample Product loading/unloading areas One soil sample must be collected and analyzed from each rack and remote fill location. Tank truck/vehicle fueling areas One soil sample must be collected from beneath each tank truck/vehicle fueling area when surface cover is soil or gravel. Additionally, at least one soil sample must be collected beneath each product dispenser. Containment drain port discharge area One soil sample must be collected from beneath each soil or gravel covered discharge area. Aboveground piping Surficial soil must be visually screened and sampled when organic vapor is detected or petroleum soil staining is observed. Underground piping It is recommended that underground product piping be removed during tank closure. If the line is abandoned in place it must be emptied of product and capped on the ends. Underground piping must be sampled at all points where a change in product flow direction occurs within the piping (turns). If piping is removed, samples must be obtained from native soil directly below the piping. If piping is left in place, a soil sample boring must be advanced within 3 feet of the piping and screened for the presence of a release to a minimum of 10 feet below ground surface. Visual Assessment

If all of the conditions below are true, contact OPS about potentially eliminating the need for tank-related sampling.

- ASTs are double-walled or are located within secondary containment

- All fill connections and dispensers are located on the top of the tank

- Complete monthly release detection records are available

- No visible staining is present

Sample Location for ASTs Located on Soil, Synthetic or Clay Liner Foundation

- The footprint of the tank must be visually inspected for soil staining and sampled if staining is present.

- If no staining is present, the soil foundation area must be screened in three equally-spaced locations around the tank perimeter to a minimum of three feet below ground surface.

- Special attention must be given to product transfer pumps and the areas where product enters or exits the tank. A minimum of one soil sample must be collected from a screened location that exhibits the highest detection of organic vapor or visually-identified soil staining.

- If organic vapor or stained soils are not encountered, soil samples from beneath product transfer pumps and areas where the product enters or exits the tank must be collected and analyzed in a laboratory.

Sample Location for ASTs Located on Concrete Slabs or Within Concrete or Similar Secondary Containment.

- Soil screening and sampling must take place adjacent to the AST foundation slab or containment structure.

- If staining is present, samples of the stained soils must be collected. If staining is present on a foundation slab or within a containment structure, soil screening/sampling must be conducted in the native soil immediately adjacent to the staining.

- If no staining is present, a sampling location adjacent to the center of each side or adjacent to the corners of a tank foundation slab or containment will be required.

- The structural integrity of the slab or containment must be evaluated and samples collected and analyzed beneath areas that have been compromised.

Additional Resources

- Best Industry Procedures for UST Removal

- American Petroleum Institute Recommended Practice 1604, Removal and Disposal of Used Underground Petroleum Storage Tanks

- American Petroleum Institute Publication 2015, Cleaning Petroleum Storage Tanks

- American Petroleum Institute Recommended Practice 1631, Interior Lining of Underground Storage Tanks

- New England Water Pollution Control Commission, Tank Closure Without Tears: An Inspectors Safety Guide

- Best Industry Procedures for AST Removal