Storage Tank System Design

Storage tank systems, USTs and ASTs must prevent releases due to structural failure, corrosion, or spills and overfills for as long as the tank system is used to store regulated substances.

Tank Design

Tank construction materials must be compatible with the substance being stored.

Because the chemical and physical properties of renewable fuels (such as ethanol and biodiesel blends) and hazardous substances may make them more aggressive to certain tank system materials than petroleum, it is important that all tank system components in contact with these liquids are materially compatible.

- When a UST will store diesel fuel containing more than 20% biodiesel or gasoline containing more than 10% ethanol, the tank owner/operator must demonstrate that all tank system components are compatible with the substance being stored by documenting the substance change on the Alternative/ Renewable Fuels Compatibility Form.

Atmospheric Tanks cannot be used to store liquids at temperatures at or above their boiling point and must be designed and constructed in accordance with recognized engineering standards.

- USTs must meet the design standards, specifications, and requirements provided in OPS storage tank regulations, U.S. EPA regulations and NFPA fire code.

- Secondary containment and interstitial monitoring is required for all new underground tank installations. If an existing underground tank is replaced, the secondary containment and interstitial monitoring requirements apply only to the replaced underground tank. These requirements do not apply to repairs meant to restore an underground tank to operating condition.

- Any portion of an underground tank that routinely contains product must be protected from corrosion in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory, such as being:

- Constructed of fiberglass-reinforced plastic.

- Constructed of steel and Cathodically Protected.

- NACE. Corrosion Control of Underground Storage Tank Systems by Cathodic Protection

- ANSI/UL 1746, Standard for External Corrosion Protection Systems for Steel Underground Storage Tanks

- Pre-engineered cathodic protection systems

- Composite Tanks

- Jacketed Tanks

Tanks that are designed and intended for aboveground use must not be used as underground tanks.

- ASTs must meet the design standards, specifications, and requirements provided in OPS storage tank regulations and NFPA fire code.

- API Specification 12B, Bolted Tanks for Storage of Production Liquids

- API Specification 12D, Field Welded Tanks for Storage of Production Liquids

- API Specification 12F, Shop Welded Tanks for Storage of Production Liquids

- API Standard 650, Welded Steel Tanks for Oil Storage

- ANSI/UL 80, Standard for Steel Tanks for Oil Burner Fuel

- ANSI/UL 142, Standard for Steel Aboveground Tanks for Flammable and Combustible Liquids

- UL 2080, Standard for Fire Resistant Tanks for Flammable and Combustible Liquids

- ANSI/UL 2085, Standard for Protected Aboveground Tanks for Flammable and Combustible Liquids

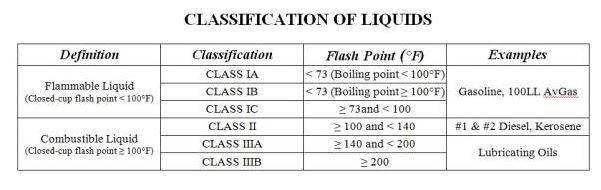

- Tanks constructed of combustible materials (such as plastic) are subject to OPS approval and are limited to use where:

- They are required by the properties of the liquid stored

- They will store Class IIIB liquids above ground in areas not exposed to a spill or leak of Class I or Class II liquids

- They will store Class IIIB liquids inside a building that is protected by an approved automatic fire extinguishing system

Tanks that are designed and intended for underground use must not be used as aboveground tanks.

Piping Design

Piping materials must be compatible with the substance that it will contain, and must be maintained liquid-tight.

Piping must be designed and constructed in accordance with recognized engineering standards.

- Underground piping must meet the design standards, specifications, and requirements provided in OPS storage tank regulations, U.S. EPA regulations and NFPA fire code.

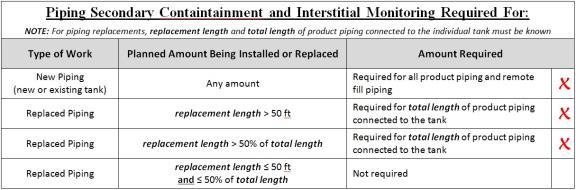

- Secondary containment and interstitial monitoring is required for all new piping installations, including piping to remote fill connections.

- For replaced piping, secondary containment and interstitial monitoring is required for the total length of piping connected to a single UST whenever more than 50% or 50 feet (whichever is less) of the piping connected to that tank is replaced.

-

- Installation of new or replaced piping will require the installation of containment sumps (under-dispenser [UDC], submersible turbine pump [STP] or transition) on both ends of the secondarily contained pipe for interstitial monitoring.

- Piping that routinely contains product and is in contact with the ground must be protected from corrosion in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory, such as being:

- Installation of new or replaced piping will require the installation of containment sumps (under-dispenser [UDC], submersible turbine pump [STP] or transition) on both ends of the secondarily contained pipe for interstitial monitoring.

- Constructed of fiberglass-reinforced plastic or other non-metallic material.

- UL 971, Standard for Nonmetallic Underground Piping for Flammable Liquids

- UL 567, Standard for Emergency Breakaway Fittings, Swivel Connectors and Pipe-Connection Fittings for Petroleum Products and LP-Gas

- UL 567A, Standard for Emergency Breakaway Fittings, Swivel Connectors and Pipe-Connection Fittings for Gasoline and Gasoline/Ethanol Blends with Nominal Ethanol Concentrations up to 85 Percent (E0 - E85)

- UL 567B, Standard for Emergency Breakaway Fittings, Swivel Connectors and Pipe-Connection Fittings for Diesel Fuel, Biodiesel Fuel, Diesel/Biodiesel Blends with Nominal Biodiesel Concentrations up to 20 Percent (B20), Kerosene, and Fuel Oil

- Standard for Nonmetallic Underground Piping for Flammable and Combustible Liquids

- Standard for Flexible Underground Hose Connectors for Flammable and Combustible Liquids

- Constructed of steel and cathodically protected.

- Aboveground piping must meet the design standards, specifications, and requirements provided in OPS storage tank regulations and NFPA fire code. This includes all valves, fittings, connectors, and all other pressure-containing parts.

- Must meet ASME B31, International Code For Pressure Piping Systems requirements.

- Cast iron, brass, copper, aluminum, malleable iron, and similar materials can only be used on tanks storing Class IIIB liquids where the tanks are located outdoors and are not within a diked area or drainage path of a tank storing a Class I, Class II, or Class IIIA liquid.