Tank System Operation

Conducting your routine inspections and staying on top of release detection requirements will go a long way toward preventing releases and ensuring a safe fueling environment for your customers. The information provided below should help you keep track of your inspection and testing requirements.

Operational requirements include:

- Monitoring tanks and lines for evidence of leaks

- Maintaining continuous corrosion protection on steel components

- Maintaining spill prevention equipment, such as spill buckets and overfill prevention devices

New Regulations Effective January 1, 2017

The Environmental Protection Agency (EPA) finalized its revisions to the Federal Underground Storage Tank Regulations in July 2015.

OPS already adopted a number of these changes in our 2008 regulation revisions, including:

- Secondary containment

- Operator training

- Monthly and annual compliance inspections

- Delivery prohibition

In order to further prevent petroleum releases, OPS adopted the remaining changes into the Colorado Storage Tank Regulations that went into effect on January 1, 2017.

The most significant new changes include the following periodic testing and inspections, which are required by January 1, 2020.

Additional changes include:

- As of January 1, 2017, ball float valves can no longer be used as a UST's primary overfill prevention device if they are found to be malfunctioning. Also, ball float valves cannot be the primary overfill prevention device in UST installations after January 1, 2017. A different overfill prevention device must be used (drop tube fill valve, audible alarm, etc.).

- Owners of existing USTs used solely for emergency generators must begin performing release detection on the tanks and piping by January 1, 2020. Owners of USTs installed after January 1, 2017, used solely for emergency generators must perform release detection as soon as they are put into use.

- Owners of retail motor fuel meters (dispensers) must notify OPS when meters are adjusted or put into service.

Details of these regulations are available on the OPS Regulations website, and we encourage you to familiarize yourself with them and use our Contact OPS Form to discuss any questions you may have.

Release Detection

Owners/operators must conduct release detection that can detect a release from any part of the tank system that routinely contains regulated substances. Ongoing release detection is required while tanks are in use. Common release detection methods are described below.

- Interstitial Monitoring

Interstitial monitoring detects liquid in the space between the primary tank or product line and its secondary containment. This includes the interstitial space of double-walled tanks or lines, as well as secondary containment sumps, such as under-dispenser containment, piping transition sumps and submersible turbine pump containment areas.

This release detection method commonly uses electronic sensors placed in the secondary containment areas. It is critical that these sensors be installed and maintained appropriately in order to detect the presence of fuel.

All UST systems installed after August 1, 2008, are required to use monthly interstitial monitoring.

- Automatic Tank Gauging

ATG (Automatic Tank Gauging) is an approved monthly monitoring method for tanks and pressurized lines. An ATG system consists of a probe installed inside each tank. The probes are wired to an electronic console that is mounted on the wall inside the facility. The automated process monitors and analyzes fuel levels to determine if there has been a suspected release. The console interprets and stores information transmitted by the probes. Most consoles have the ability to print out a tape with the results of the tests, and many can be connected to your computer network to allow electronic management of these records.

- Statistical Inventory Reconciliation

SIR (Statistical Inventory Reconciliation) is an approved monthly monitoring method for tanks and lines. The tank owner/operator provides daily inventory, delivery and dispensing data to the SIR vendor. The vendor's computer software statistically analyzes the data provided to determine whether a tank system is leaking. The vendor provides a monthly report of that analysis to the tank owner. Using SIR does not relieve tank owners/operators of the requirement to equip all pressurized lines with operational in-line leak detectors and test the leak detectors every 12 months in accordance with the manufacturer's requirements

- Manual Tank Gauging

Manual tank gauging is an approved monthly monitoring method for a limited population of tanks. It may be used as the sole method of release detection for USTs of 1,000 gallons or less, or for USTs between 1,000 and 2,000 gallons if they are less than 10 years old and if tank tightness testing is performed at least every five years.

Tank liquid level measurements must be based on an average of two consecutive stick readings taken at least 36 hours apart. No liquid should be added to or removed from the tank during this period.

Corrosion Protection

You need corrosion protection if your system includes metallic components that are in contact with soil or water. The two common methods of corrosion protection are galvanic anodes and impressed current.

- Galvanic Anodes

Smaller tank systems, steel pipe or isolated steel fittings typically utilize the installation of magnesium or zinc anodes. These anodes connect to the steel tank system components and create a negative current.

Galvanic anode system

This current is created by the difference in corrosion potential of dissimilar metals; the faster-corroding anode material will protect the steel, thus the term "sacrificial anode."

Sacrificial anode

- Impressed Current

Tank systems that cannot be protected with galvanic anodes use an external applied electrical current to provide corrosion protection.

Impressed current system

A DC rectifier is used to control the power supply. The rectifier's negative terminal is connected to the tank system and the positive terminal is connected to anodes buried around the tank.

Impressed current rectifier

Spill Prevention

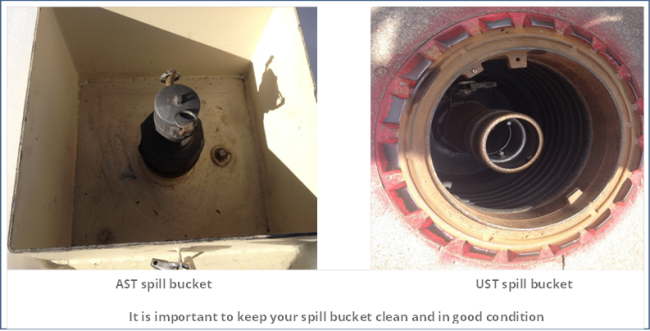

Spill Buckets

The spill containment device, also known as a spill bucket, is used to contain fuel during loading and unloading activities. This required piece of equipment is the first line of defence to preventing a release of petroleum to the environment.

Reminder: When responding to OPS records requests, remember to keep copies of any submittal for your records.

A thorough inspection of the spill bucket is required during your monthly and annual inspections. During these inspections, ensure that your spill bucket is free of any fuel, water or debris. The spill bucket should be cleaned regularly, well-maintained and free of any visible damage.

A Spill Prevention, Control and Countermeasure Plan is required by the US EPA for qualifying AST systems. All requests for information regarding Spill, Prevention, Control and Countermeasure Plans should be directed to the US EPA.

Overfill Prevention

Owners/operators must ensure safe delivery of fuel by:

- Painting your lids or clearly identify fill ports

- Sticking your tanks before delivery or calculating ullage

- Checking for functional overfill prevention devices

Tank ullage is a method of determining the amount of unfilled space in a container or the available tank capacity. This measurement is based on direct liquid level measurement that is converted to gallons. Product deliveries should not begin until the delivery operator has determined tank ullage.

USTs are required to have an overfill prevention device, such as a drop tube valve or ball float if deliveries to the tank exceed 25 gallons.

If your AST is equipped with an overfill protection device or an audible overfill alarm that can be heard by the delivery operator, you meet the release prevention requirements and are not required to submit ullage logs to OPS.

If your AST is not equipped with one of these devices, the tank ullage and the amount of product delivered must be documented on the AST Ullage Log, and the records should be maintained for a minimum of 12 months.

Ongoing Maintenance

Keep water out of the fuel. Water can enter the tank in many ways. One of the most common pathways for water to enter the tank is through the drain valve located at the bottom of a spill bucket. Over time, the drain valve can leak and water in the spill bucket from storm runoff can enter the tank.

Are all the tank openings properly sealed? Ensure that all caps, plugs, fittings and flanges are sealed and watertight. To maintain fuel quality (free of water), it is recommended to gauge for water on a regular basis.

It is important to keep water out of your tank to prevent internal corrosion as shown here.

Record Keeping

OPS inspectors will request and review your compliance records as part of their State inspection of your facility. Please keep the following in mind when responding to the request for records.

- Make copies or scans of the applicable records when responding to a records request (keep your original copies).

- Communicate with your inspector if you have any issues acquiring and submitting the requested records by the requested date.

OPS recommends keeping these records indefinitely since they may be required as part of the compliance review for reimbursement applications to the Petroleum Storage Tank Fund. However, the following table lists the minimum record retention requirements:

| Retention Time Frame | AST | UST |

|---|---|---|

| 1 year |

|

|

| 2 years |

|

|

| 5 years |

|

|

| Until tank Closure |

|

|

Exemptions or Variances

Variances to the storage tank regulations are uncommon. However, if you provide a legitimate reason for an exemption and are unable to fulfill the requirements from any portion of regulation, a variance may be requested. OPS will not consider a variance without approval from the local fire department and evidence that measures are in place to demonstrate equal protection of public safety, human health and the environment.

OPERATING REQUIREMENTS FOR UNATTENDED FUELING FACILITIES

The following items found in NFPA 30A are required, in addition to other basic requirements, where the dispensing of motor fuels at self-service facilities occur without an attendant or supervisor present:

- Fuel dispensing systems must be provided with one or more clearly identified emergency shutoff devices or electrical disconnects that are readily accessible to patrons. These devices or disconnects must be installed in approved locations not less than 20 ft. or more than 100 ft. from the dispensing devices they serve. The devices or disconnects must disconnect power to all dispensing devices, to all remote pumps serving the devices, to all associated power, control, and signal circuits, and to all other electrical equipment in the hazardous location surrounding the dispensing devices. Where more than one shutoff device or disconnect is provided, they all must be interconnected. A manual reset of the emergency shutoff condition is required.

- A fire extinguisher with a minimum rating of 40-B, and located no more than a 30 ft. travel distance from the dispensing devices must be accessible to patrons.

- Warning signs must be posted in the dispensing area, in a conspicuous location, where they can easily be read and must incorporate the following or equivalent wording

WARNING

It is unlawful and dangerous to dispense gasoline into unapproved containers.

No smoking.

Stop motor.

No filling of portable containers in or on a motor vehicle.

Place container on ground before filling.

Discharge your static electricity before fueling by touching a metal surface away from the nozzle.

Do not re-enter your vehicle while gasoline is pumping.

If a fire starts, do not remove nozzle — back away immediately.

Do not allow individuals under licensed age to use the pump. - Operating instructions must be posted in the dispensing area, in a conspicuous location, when they can easily be read. These instructions must include the location of emergency shutoff devices, fire extinguishers, and a requirement that the user stays outside of their vehicle and in view of the fueling nozzle during dispensing.

- Emergency instructions must be posted in the dispensing area, in a conspicuous location, where they can easily be read and must incorporate the following or equivalent wording:

EMERGENCY INSTRUCTIONS

In case of fire or spill:

- Use the emergency stop button.

- Report accident by calling (911 or local fire number) on the phone. Report location.

- A telephone or other approved, clearly identified means to notify the fire department must be provided on the site in an approved location.

- All dispensing nozzles must be a listed, pressure-sensitive, automatic-closing type equipped with latch-open device.

When and How to Contact OPS

It is important that OPS has complete and accurate information regarding each facility's tank system and ownership. The following table outlines the most common reasons for contacting OPS.

| Reason for Notification | Means of Notification |

|---|---|

| Change in ownership | UST Transfer of Ownership form or AST Transfer of Ownership form |

| Change in primary contact | Email the Oil Inspection Section, Telephone or Mail |

| Change in A/B Operator | A/B Operator Designation form (with a copy of the operator training certificate) |

| Change in product type | Change of Product form and Renewable Fuels Compatibility form (if necessary) |

| Change in release detection method | Email the Oil Inspection Section or Mail |

| Change in tank status: temporary closure | UST Temporary Closure Notification form or AST Temporary Closure Notification form |

| Change in tank status: permanent closure or change in service | Permanent Closure or Change in Service Notice form |

| Change in tank status: placing back into service | Notice of Intent to Place UST Back into Service form or Notice of Intent to Place AST Back Into Service form |

| Equipment failure, need for repair or upgrade | UST Minor Equipment Repair/Replacement Notification form or UST Upgrade Application or AST Upgrade Application |

| Suspected release conditions | Call the OPS Technical Assistance Line: (303) 318-8547 |