Chemicals of Concern (COCs)

Regulated substances, especially ones with a petroleum component, may contain COCs that can harm human health or the environment. For instance, a typical gasoline mixture contains about 150 different hydrocarbons, including benzene, toluene, ethylbenzene, total xylenes, and naphthalene (BTEXN) compounds, butane, pentane, and isopentane. The characteristics of gasoline depend on the type of crude oil used to produce it and the setup of the refinery that produces the blend stocks. Most finished motor gasoline is produced at blending terminals. The blend stock from the refinery is blended with finished gasoline, fuel ethanol, and other additives, such as lubricants, anti-rust agents, anti-icing agents, or detergents, to produce the various grades and formulations of gasoline for retail sale. The blends also vary seasonally and by altitude, so there is a great deal of variation.

A regulated substance released from a storage tank system may pose an unacceptable risk to public health or the environment. It is important to note that the extent of all associated COCs must be vertically and horizontally defined. Further information is provided in Section 9 (Site Characterization). Table 2 provides a list of regulated substances and analytes. A list of COC Tier I RBSLs is included in Table 3. If a contaminant from a regulated storage tank system is not listed in Table 3, OPS will default to EPA standards.

Regulated substances originating from a storage tank system that is not regulated by OPS are regulated by CDPHE.

Primary COCs

Due to their prevalence in regulated petroleum products, toxicity, and mobility in the subsurface, the following primary COCs have been identified:

- Benzene

- Toluene

- Ethylbenzene

- Xylenes

- Naphthalene

- Total Petroleum Hydrocarbons (TPH)

Primary COCs must be characterized in all media (soil, groundwater, and soil vapor). Benzene, ethylbenzene, and naphthalene are primary COCs based on their carcinogenic and toxicological properties, while toluene and xylenes are primary COCs based on their toxicological properties.

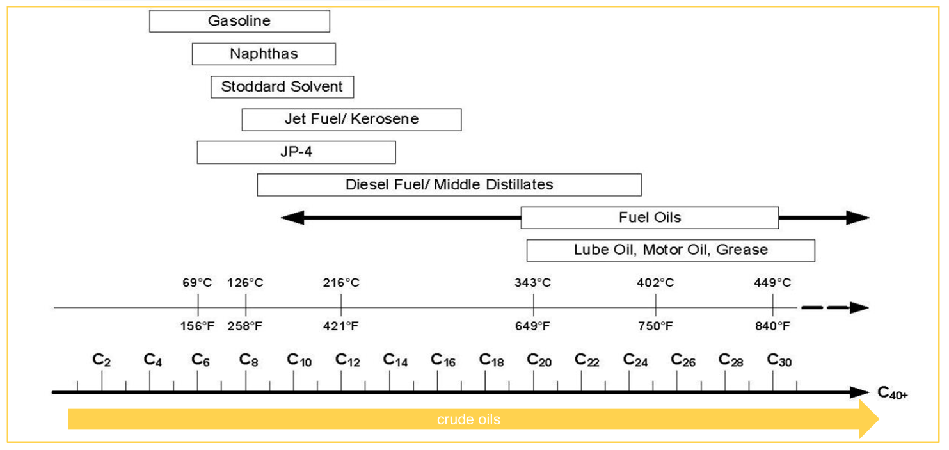

TPH characterization is required in soil and groundwater. TPH has a threshold limit intended as a screening standard, not a remedial standard, to determine when investigation of Polycyclic Aromatic Hydrocarbons (PAHs) is required. The type of TPH that should be assessed will depend on the type of petroleum lost from the tank system, as indicated below.

TPH is divided into the following three (3) groups based on the number of carbons, which is reflective of the fuel type:

- Total Volatile Petroleum Hydrocarbon/Gasoline Range Organics (TVPH/GRO)

- Total Extractable Petroleum Hydrocarbons/Diesel Range Organics (TEPH/DRO)

- Total Recoverable Petroleum Hydrocarbons/Oil Range Organics (TRPH/ORO)

Table 5.1 - Carbon Ranges for Refined Fuels and Oils

Source: TPHCWG (1999)

Secondary COCs

Secondary COCs include:

- Polycyclic Aromatic Hydrocarbons (PAHs)

- Fuel Additives and Degradation Products

Polycyclic Aromatic Hydrocarbons (PAHs)

EPA has identified 16 Priority PAHs based on carcinogenic and toxicological properties. However, OPS requires the analysis of only the following 13 Priority PAHs with exposure standards:

- Acenaphthene

- Anthracene

- Benz(a)anthracene

- Benzo(a)pyrene

- Benzo(b)fluoranthene

- Benzo(k)fluoranthene

- Chrysene

- Dibenzo(a,h)anthracene

- Fluoranthene

- Fluorene

- Indeno(1,2,3-cd)pyrene

- Pyrene

- Naphthalene (considered a primary COC. See Section 5.1. Primary COCs)

These secondary PAHs must be analyzed when TEPH or TRPH exceed the 500 mg/kg threshold limit value (TLV) in soil. Secondary PAHs must be analyzed from the soil sample with the greatest TEPH or TRPH concentration exceeding 500 mg/kg for each release.

If the unsaturated soil sample with the highest TEPH or TRPH concentration exceeding 500 mg/kg collected at the site does not exceed PAH Tier I RBSLs, further PAH characterization is not necessary for the release.

FAQ: How many times must I analyze for PAHs?

OPS requires the soil sample with the greatest TEPH or TRPH concentration (above 500 mg/kg) to be analyzed for PAH content. During a typical phased investigation, if subsequent soil samples contain greater TEPH or TRPH concentrations than prior sample(s), PAH analysis should be repeated for that phase of work on that soil sample.

For example, if soil samples collected during four phases of a specific source area investigation contained TEPH or TRPH concentrations of: (1) 350, (2) 700, (3) 550, and (4) 800 mg/kg. The first sample would not require PAH analysis. The second sample would require PAH analysis (it exceeds 500 mg/kg). The third sample would not require PAH analysis (it exceeds 500 mg/kg but it is less than the prior analysis of 700 mg/kg). The fourth sample would require PAH analysis once it is found to contain the greatest concentration of TEPH or TRPH to date. Always notify your laboratory.

If any PAH concentration exceeds Tier I RBSLs in an unsaturated soil sample, the horizontal and vertical extent of PAHs should be defined to below Tier I RBSLs. If PAHs exceed Tier I RBSLs in the capillary fringe or smear zone, groundwater samples should be collected for PAH analysis. Because of the possibility of PAHs from other sources (e.g., airborne deposition from automobile combustion, coal-tar-based pavement sealers, recycled asphalt fill, oils for dust control, etc.), a background groundwater sample must also be collected for PAH analysis at a location upgradient from the plume.

Fuel Additives and Degradation Products

Various compounds have been added to gasoline over the years to enhance certain performance properties of the fuel. These compounds should be evaluated based on the history of the petroleum storage systems used at the facility location. Figure 5.2.2 indicates which additives should be included during initial characterization.

Figure 5.2.2 - Historical Use of Fuel Additives in Colorado

| Fuel Additive/Degradation Product | Date of Use in Colorado |

|---|---|

| 1,2-Dichloroethane (1,2-DCA) | Through 1/1/1996 |

| Ethylene Dibromide (EDB) | Through 1/1/1996 |

| Tetraethyl Lead (TEL) | Through 1/1/1996 |

| Methyl-Tertiary Butyl Ether (MTBE) | 1979 - 5/1/2002 |

| Ethanol | 1996 - current |

Note: Past site characterizations may have eliminated the need for additional assessment of previously investigated compounds. Be certain to check OPS records for such information.

If these compounds are identified during characterization, additional monitoring and remediation will be handled on a site-specific basis.

1,2-Dichloroethane (1,2-DCA), Ethylene Dibromide (EDB) and Tetraethyl Lead (TEL)

Before 1996, 1,2-DCA (aka Ethylene Dichloride) and EDB (aka 1,2 Dibromoethane) were used as additives in leaded gasoline. 1,2-DCA was an anti-knock additive for leaded gasoline, and EDB was a lead scavenger in anti-knock gasoline mixtures (particularly in aviation fuel). Both are COCs based on carcinogenic and toxicological properties and are potential carcinogens via inhalation, absorption, ingestion, and direct contact exposure pathways. A release site must be assessed for the presence of 1,2-DCA and EDB if the site is suspected to have dispensed leaded gasoline or operated before 1996. This may involve investigation in areas of the facility other than the impacted area of the current release, even if the current release does not involve leaded fuels or groundwater (e.g., a diesel release or a surface spill).

Beginning in 1978, TEL was the chief anti-knock additive until it was gradually phased out by January 1996. TEL is considered a COC with the potential to cause acute or chronic lead poisoning if inhaled, ingested, or absorbed through the skin. A release site must be analyzed for TEL in surficial soils if the site is suspected to have dispensed leaded gasoline or operated before 1996. This may involve investigation in areas of the facility other than the impacted area of the current release, even if the current release does not involve leaded fuels or groundwater (e.g. a diesel release, or a surface spill).

Facilities currently dispensing leaded gasoline (e.g. racing or aviation fuel) must be assessed for 1,2-DCA, EDB, and TEL as described in Section 6.

Methyl-Tertiary Butyl Ether (MTBE)

MTBE is a gasoline oxygenate that was used in Colorado possibly from as early as 1979 until April 30, 2002, when it was banned. Although the EPA has not set a national standard for MTBE in drinking water, a Drinking Water Advisory was issued in 1997 that established a taste threshold of 0.04 milligrams per liter (mg/l) and an odor threshold of 0.02 mg/l.

Ethanol

Since 1996, ethanol has been a common oxygenate additive for gasoline and may comprise 6-85% of the total fuel volume. Methane is a degradation product of ethanol and would most likely be found in soil vapor within the unsaturated zone (see section 6.3). Methane is non-poisonous but can be an asphyxiant and an explosive hazard when mixed with air within a specific concentration range. In addition to the primary COCs, a release site should be assessed for methane vapor if the facility stored E-85 blended fuel at the time of the release.

Other Regulated Compounds

Other regulated products commonly used for commercial purposes include new lubricating oil, used oil, methanol, petroleum solvents, and glycols. A release site should be assessed for these regulated compounds if a release is confirmed to be from a regulated tank that contained these products or if there is knowledge of the facility location having stored these products in the past. If these COCs are identified during characterization, additional monitoring and remediation will be handled on a site-specific basis.

New Lubricating Oil and Used Oil

BTEXN and TRPH are required analytes for assessing releases from new lubricating oil tanks. BTEXN, TVPH, TEPH, and TRPH are required analytes for assessing releases from used and waste oil tanks. PAH analysis is required in accordance with section 5.2.1.

Used and waste oils may also contain solvents and/or degreasers. In addition to BTEXN, TVPH, TEPH, and TRPH, a full analysis of volatile organic compounds (VOCs) is required during the initial release characterization of used and waste oil to determine if any non-petroleum hazardous contaminants present could adversely affect the environment.

Methanol

Although storage tanks containing methanol are not prevalent in Colorado, methanol can be occasionally used as a solvent, blended with gasoline (the ASTM standard on gasoline (D4814) limits methanol content to no more than 0.3% in gasoline), or for other purposes. If the release is primarily associated with a methanol tank system, methane and carbon dioxide in vapor media should be characterized.

Petroleum Solvents

Petroleum solvents include rubber solvents, mineral spirits, paraffin, and naphtha. A full analysis of VOCs is required.

Glycols

Glycols are organic compounds that contain alcohol. The most common glycols are ethylene glycol and propylene glycol, which are used as antifreeze in automotive cooling systems and airport de-icing operations. OPS would be the lead remediation agency if the glycol(s) are sourced from a used oil tank. In that situation, analysis of glycols in soil, groundwater, and soil vapor, as well as methane in soil vapor, is recommended. A discussion with an OPS environmental specialist is encouraged to determine the appropriate sampling plan.

Hazardous Waste

Solid waste is a hazardous waste if it contains a compound listed as a known hazardous waste or meets the characteristics of hazardous waste under 40 CFR 261. Characteristic wastes are wastes that exhibit any one or more of the following characteristic properties: ignitability, corrosivity, reactivity, or toxicity. Listed hazardous wastes are wastes from common manufacturing and industrial processes and can be generated from discarded commercial products.

At the time of promulgation of the final toxicity characteristic (TC) rule, EPA decided to temporarily defer the applicability of the TC rule to media and debris contaminated with petroleum from USTs subject to the corrective action requirements of Subtitle I of RCRA. EPA had little information regarding the full impact of the TC rule on UST cleanups; however, a preliminary assessment indicated that the number of UST cleanup sites and the amount of media and debris at each site that would exhibit the toxicity characteristic would be extremely high. EPA reasoned that subjecting all, or even a portion of these sites to Subtitle C requirements would overwhelm the hazardous waste permitting program and the capacity of existing hazardous waste treatment, storage, and disposal facilities. In addition, imposition of the requirements could delay UST cleanups significantly (58 FR 8504; February 12, 1993).

Therefore, petroleum-contaminated media and debris, such as soil and groundwater, that are generated from petroleum UST corrective action activities under 40 CFR Part 280 are excluded from the definition of hazardous waste. The definition of a UST generally includes those tanks or combinations of tanks whose volume, including the volume of underground connected piping, is ten percent or more beneath the ground’s surface (40 CFR 280.12). Any tank that does not meet this definition, with exceptions as noted, is not a UST, would not qualify for the hazardous waste exclusion in 40 CFR 261.4(b)(10), and thus would be subject to comprehensive requirements for the reporting and cleanup of soil and groundwater if deemed hazardous.

It is important to note that the exemption does not apply to media and debris generated from AST corrective action. Therefore, waste that fails the 40 CFR 261.24 TC test requirements is subject to hazardous waste handling and disposal.

Additionally, OPS will contact CDPHE if non-petroleum hazardous contaminants, such as chlorinated solvents from a dry cleaner, are present. However, OPS will not notify CDPHE if chlorinated volatile organic compounds (CVOCs) (including EDB/1,2-DCA) are sourced from the regulated tank with other petroleum products.

A facility owner or operator must make a good faith effort to determine if a material is a listed hazardous waste. However, if an owner or operator cannot make such a determination because documentation regarding a source of contamination, contaminant, or waste is unavailable or inconclusive, the owner or operator may assume the source, contaminant, or waste is not a listed hazardous waste and, provided the material in question does not exhibit a characteristic of hazardous waste, RCRA requirements do not apply (Management of Remediation Waste Under RCRA, EPA530-F-98-026).

If the tank isn’t considered empty (i.e., has greater than one inch of residue/product) and the contents being discarded have certain characteristics or are listed in 40 CFR 261, they may be classified as a regulated hazardous waste. The waste should be tested and it must be stored, handled, and disposed of in accordance with CDPHE guidance if it meets the criteria of a hazardous waste.

References

TPHCWG (1999), Human Health Risk-Based Evaluation of Petroleum Contaminated Sites: Implementing the Working Group Approach. Association for Environmental Health and Sciences Total Petroleum Hydrocarbon Criteria Working Group Series, Volume 5. Retrieved from: TPH Working Group Series, Volumes 1-5 | AEHS

EPA Takes Final Step in Phaseout of Leaded Gasoline

Gasoline | Methyl Tertiary Butyl Ether (MTBE) | US EPA

Health and Environment Assessment of MTBE: The California Perspective

Federal Register (1993), EPA 40 CFR Part 261 Exemption of Petroleum-Contaminated Media and Debris From Underground Storage Tanks From RCRA Hazardous Waste Requirements: Proposed Rule. Retrieved from:

EPA Management of Remediation Waste Under RCRA, EPA530-F-98-026